Laboratory homogenizers | COLO.Science cover the core technologies used to turn heterogeneous samples into stable, representative extracts for analysis. Whether you process biological tissues, food matrices, environmental sediments or formulation samples, the right homogenizer improves repeatability, reduces prep time and standardizes downstream results across daily workflows.

This category brings together key homogenization approaches—from rotor–stator dispersing homogenizers (high-shear emulsification/dispersion), to bag blenders (Stomacher) (sterile homogenization in disposable bags), and ultrasonic homogenizers (probe sonication for cavitation-based disruption). Selecting the correct method depends on sample type, viscosity, volume, contamination risk, heat sensitivity, and the level of particle size reduction required.

HOMOGENIZER TECHNOLOGY GROUPS

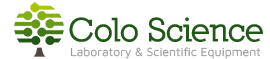

- Ultrasonic homogenizer – probe sonication for cavitation-based dispersion and cell disruption.

- Bag blender (Stomacher) – sterile paddle homogenization inside disposable filter bags.

- Dispersing homogenizer – high-shear rotor–stator mixing for emulsions, suspensions and powders.

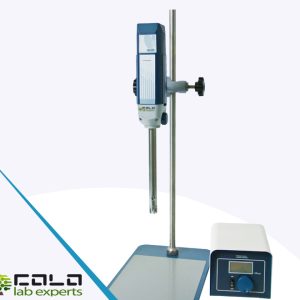

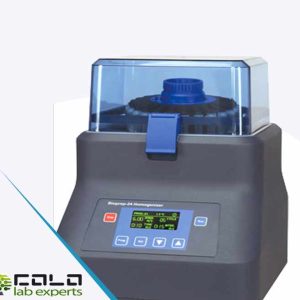

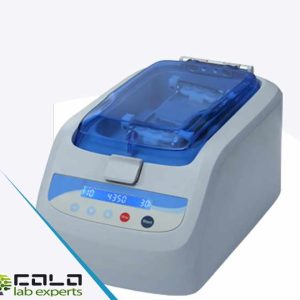

- Bead/tube homogenizers – sealed tube disruption for tough tissues and robust extraction workflows.

SELECTION & TECHNICAL GUIDANCE

- Sample type – tissues and cells often need sonication or bead disruption; food and soft matrices often suit bag blenders.

- Volume & throughput – match chamber/bag size, tool diameter or tube capacity to routine batches and daily load.

- Shear intensity – rotor–stator systems provide scalable shear via RPM and head geometry; sonication depends on amplitude and probe size.

- Temperature control – high-shear and cavitation can heat samples; use pulse modes and external cooling for heat-sensitive work.

- Contamination risk – sealed bags/tubes reduce cross-contamination and aerosol risk; ideal for high-throughput QC.

- Workflow standardization – prefer digital timing, reproducible positioning (stands/holders), and documented parameters (RPM/time/amplitude).

Homogenizers are used across microbiology, food safety, environmental analysis, pharmaceutical QC and formulation R&D. For best reproducibility, define your target outcome (dispersion, emulsification, cell lysis, extraction), then select the technology and accessories that match your matrix and throughput.

Homogenizers Categories

Homogenizers

Showing all 14 results