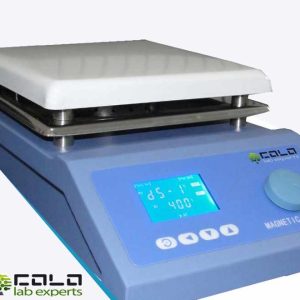

Magnetic Stirrers with Ceramic Hotplates — Digital PID Control & Dual Temperature Measurement

Magnetic stirrers with ceramic hotplate provide stable mixing and precise heating for laboratory workflows. With digital PID control and external temperature probe support, they enable accurate plate and liquid temperature measurement for reproducible results.

Magnetic stirrers with heating are core instruments for daily sample preparation in chemistry, pharma, microbiology and

industrial QC — whenever stable mixing and controlled heating must run in the same workflow. This category focuses on

ceramic hotplate magnetic stirrers, valued for high chemical resistance, easy cleaning, uniform heat distribution

and reliable performance at elevated temperatures (model-dependent).

For digital platforms, the key advantage is PID temperature regulation, which maintains the setpoint with minimal

overshoot and drift — improving repeatability for dissolution, buffer preparation, media preparation and temperature-driven

reactions. For true process control, many laboratories prefer temperature measurement on the plate and directly in the liquid

using an external probe (often Pt100 class A), because the real sample temperature depends on vessel geometry, volume,

viscosity and heat transfer efficiency.

CATEGORY STRUCTURE (NAVIGATION HUB)

- Lab Equipment

– laboratory instrumentation (main categories). - Sample Preparation

– mixing, heating, homogenization and workflow prep.- Magnetic Stirrers

– with/without heating, analog or digital (including multi-position models). - Hot Plates

- Heating Mantles

- Shakers & Mixers

- Magnetic Stirrers

MAGNETIC STIRRER GROUPS & WHAT TO LOOK FOR

- Digital ceramic hotplate stirrers – built for repeatable workflows with stable speed and temperature control;

often available with external probe input for direct liquid temperature measurement. - High-temperature digital platforms – designed for demanding thermal regimes and higher plate setpoints,

typically with improved control logic and safety monitoring. - Dual temperature measurement (plate + liquid probe) – enables plate temperature monitoring and true process

temperature control in the sample, reducing uncertainty caused by vessel and load conditions (commonly via Pt100 probes). - Multi-position magnetic stirrers – useful for parallel sample series (e.g., 4 or 10 positions) with more uniform

mixing conditions across stations. - Analog hotplate stirrers – simple and cost-effective for routine tasks, typically with a defined heating range and

basic speed control.

FEATURED: DIGITAL PID + EXTERNAL PROBE FOR LIQUID TEMPERATURE

If process temperature is critical, choose a digital platform with PID control and an

external temperature probe (dual measurement). This lets you control and document the real temperature in the solution,

not only the hotplate surface — improving reproducibility and safety for sensitive samples.

Magnetic Stirrers

Showing all 7 results