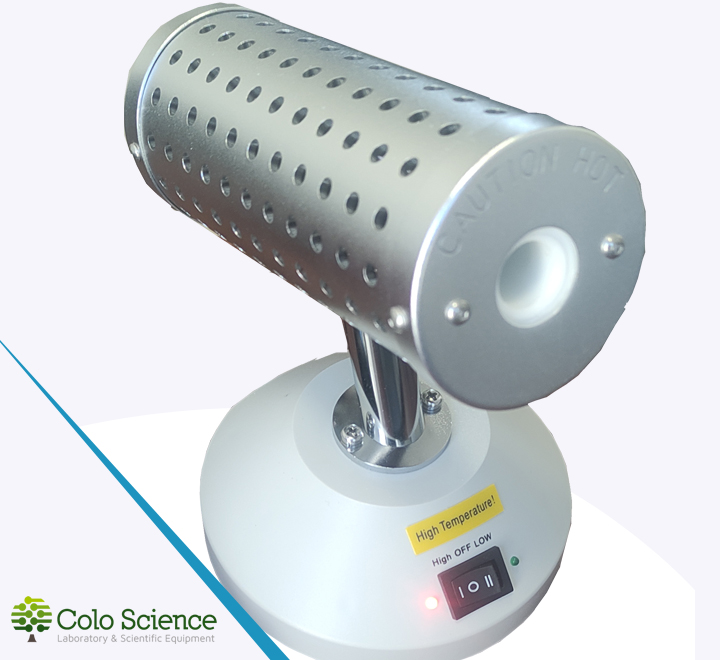

IRBACTI — Electric Sterilizer for Inoculation Loops, Ose and Needles

IRBACTI sterilizer is a compact, flameless electric device for sterilizing inoculation loops, ose, and needles in microbiology laboratories.

It replaces alcohol lamps and Bunsen burners, providing sterilization up to ~825 °C in just 5–7 s, with minimal contamination risk and without open flame or fumes.

Designed for benchtops and biosafety cabinets where stable, controlled heat is essential for reproducible results.

Consistent results with minimal handling.

- Rapid sterilization of loops, ose and needles in 5–7 seconds

- Up to 825 °C in a defined active heating zone

- Ideal for biosafety cabinets and crowded workspaces

Why IRBACTI instead of a Bunsen burner?

Flameless electric sterilization reduces risks, retains heat inside the ceramic tube, and ensures reproducible results in sterile zones.

Less consumables, faster turnaround between inoculations, and a safer workbench mean higher capacity and reliability every day.

Learn more about

laboratory sterilizers at COLO.Science

.

IRBACTI sterilizer — Safety and applications

IRBACTI provides stable high temperature in a defined heating zone, without affecting the surrounding environment.

Suitable for clinical and teaching laboratories, research institutes, microbiology workbenches, and mobile labs.

The device requires little space, consumes 150 W, and needs no additional media or consumables.

Maintenance is simple, and consistent performance reduces errors and accelerates routine culture transfers.

Quick Specifications

| Max core temperature | 825 °C ± 25 °C |

|---|---|

| Object diameter | φ15 mm |

| Heating zone length | 140 mm |

| Warm-up time | ~15 min |

| Power | 150 W |

| Voltage / frequency | AC 220 V or AC 110 V, 50–60 Hz |

| Fuse | 250 V / 3 A, 5×20 mm |

| Ambient working temperature | 5–40 °C |

| Dimensions (W × D × H) | 120 × 155 × 180 mm |